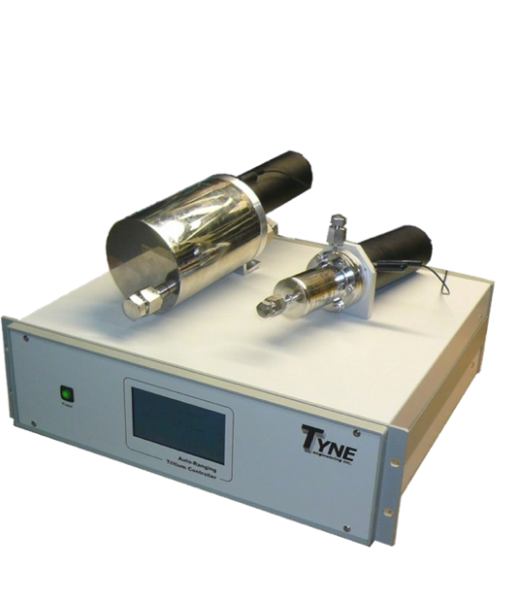

10 CC ION CHAMBER

Model 7002-10-001

The 10 cc Ionization Chamber is designed as a high activity, bakeable radiation detector. With the small footprint and VCR8 connections, the chamber is easily incorporated into any process system. The specialized ceramic feed through allows a bias of up to 100V and an anode signal as low as 1 fA (corresponds to 100 μCi/m³ of tritium). When combined with Tyne’s preamplifier and controller package or signal processor, this makes an ideal tool for measuring tritium gas concentration in any process.

Note: For lower tritium concentrations, please see Tyne’s 1000cc ion chamber.

- 10cc ion chamber suitable for mCi/m³ to kCi/m³ of Tritium.

- Virtual Wall for minimum tritium surfacecontamination.

- Can be used in explosive environments with additional purge equipment.

- Precise, tested and proven 10cc geometry.

- Can bias anode up to 100V from ground.

- Inlet precipitator.

- Bakeable to cleanse contaminated surfaces of the ionization chamber.

- Use in a process line or for room airmeasurements.

- Rated from full vacuum to 150psig

- Rated for flows up to 1 l/s.

The 10 cc Ion Chamber is designed to be an in-line process gas radiation detector with the most typical application being Tritium.

The smaller volume than the 1000cc detector and the virtual wall technology makes this the ideal choice for very high activity measurements. The inlet and outlet VCR 8 connectors allow the chamber to be easily installed in an existing process line. The internal anode is connected to a floating BNC which can be biased up to 100 V. The high resistance ceramic of the feed through allows the ionization chamber to measure ionization currents as low as 1 fA (1 μCi/m³ of Tritium). The bias voltage is also connected to an inlet precipitator to remove any incipient ionized particles avoiding being carried into the chamber. The maximum inlet flow rate of 1 L/s ensures that all particles are neutralized before entering the chamber. The ionization chamber is an approved pressure vessel that can handle up to 150 psig, is bakeable up to 350°C and is leak checked to 1x10E-9 cc/sec.

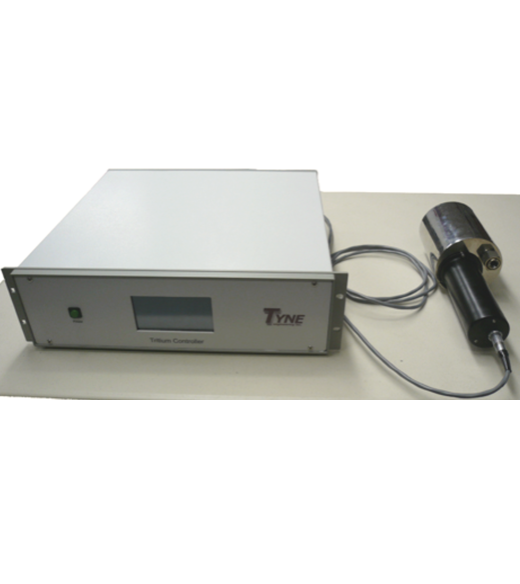

The ionization chamber is typically connected to a Tyne Engineering preamplifier or signal processor. The preamplifier is a multi-ranged amplifier that connects to a remote controller, giving the user the maximum flexibility for measuring the amount of tritium, auto zeroing and alarm functions. The signal processor is a low cost device that provides the bias and converts the 1 fA signal to an easily handled 0 – 10 V signal that can be integrated into any existing data acquisition system.

related Tritium In Process tubing Monitoring Products

Tyne has successfully designed, fabricated and tested in-line process tritium monitors for process and experimental applications across multiple industries with a wide scope of clients in the nuclear power sector. Our monitors are uniquely simple and compact in design, ultrahigh vacuum compatible, and bakeable to 350°C.