Particulate, Iodine and Noble Gas Monitors

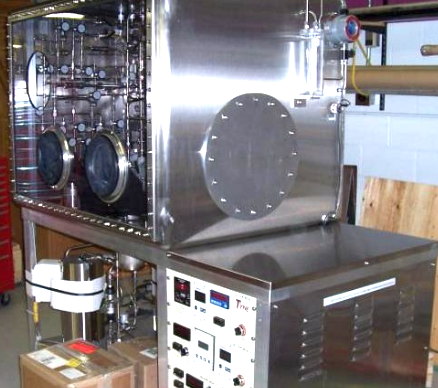

Tyne Engineering’s low range, online radiation monitor is part of Tyne’s radiation monitoring product line and was developed to continuously monitor radioactive particulate, iodine and noble gas volumetric activities in nuclear facility discharge stacks, ventilation systems and operational areas.

- Particulate, iodine and gas monitoring, beta and gamma monitoring as appropriate.

- Iodine monitoring, both elemental and organic forms, using gamma scintillation counters.

- Nobel gas monitoring, direct gamma and beta measurements to provide accurate emission monitoring of gamma emitters (Xe-133) and beta emitters (Kr-85).

- Compact, self contained skid only requiring a 115VAC supply and ethernet connection.

- Expandable to include optional tritium and carbon-14 sampling capability.

The detectors are installed within lead shielding assemblies in a 4π configuration.

Integrated total activities of particulate and iodine will be measured by accumulation of the measured sample on the filter media. Integration will be base lined at each filter change. Filter changes will be managed utilizing filter bypass valves to avoid shutting down the entire sampling system upon filter removal.

All systems rely upon the availability of Class IV 115VAC electrical power for operation. Critical systems can be provided with UPS battery back up at the customer’s request.

Noble gases will be measured directly using a Marinelli cell in near-real-time. The only delays will be the induction period in the sampling lines, the time to flush the Marinelli cell and the required counting time.

Sampling will be controlled using mass flow controllers and two positive displacement pumps (One backup) to draw the sample through the measurement chain. When the tritium and carbon 14 sampling option is selected, a lower flow rate pump is used to provide a controlled flow from the Marinelli cell exhaust to sample these gases.

The entire system will have a common human machine interface (HMI) that will interact with both the process control and the data flow from radiation detectors. The HMI will also act as the common communication hub for external communication of data from the detector skid to remote data collection and annunciation systems. Where the RMS is being used in a safety related functionality, a direct signal from the detector, prior to digitization and analysis will be conditioned to 4-20mA and forwarded to the associated safety related system.

The primary detector systems are scintillation counter based and use either single detectors or phoswich combined modality detectors depending upon the monitoring requirements. In the case of phoswich detectors, gamma and beta scintillation detectors are combined into a single assembly. The combined signals are deconvoluted using waveform separation techniques to provide singular measurements of gamma and beta radiation with minimum interference or cross-talk between the different radiation readings.

Related Tritium Handling systems

For over 25 years, Tyne Engineering has been customizing tritium handling equipment and systems for our valued clients worldwide. Our technology is designed and built using high vacuum technology. All pumps, valves and fittings are subject to our stringent quality standards.

Leak Tightness

Permeation Control

tritiated atmosphere containment

waste confinement

atmospheric cleanup

ventilation control

CSA-N286.2 by CANPAC (Nuclear Design Quality Assurance) . CSA-Z299.1 by CANPAC and QMI (Nuclear Design Quality Assurance) . EPRI-NP-5625 (for CGD by CANPAC) . ISO9001:2000 by QMI . TSSA certification to ASME Section VIII Div 1 . TSSA certification to ASME B31.1 . TSSA certification to ASME B31.3 . TSSA certification to CSA B51 . Tyne complies fully with 10CFR50 Appendix B and has been audited to ASME NQA-1 Nuclear Quality Assurance Program.