Tritium Controller

Model 7000

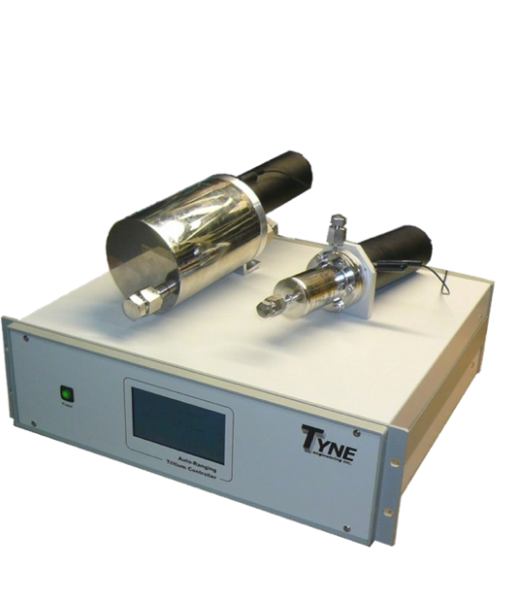

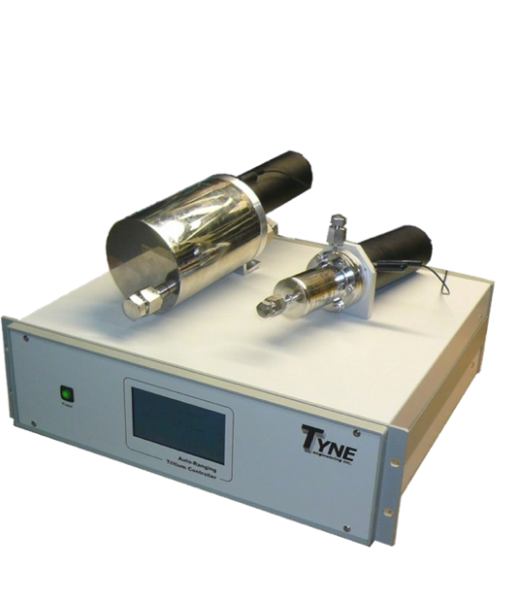

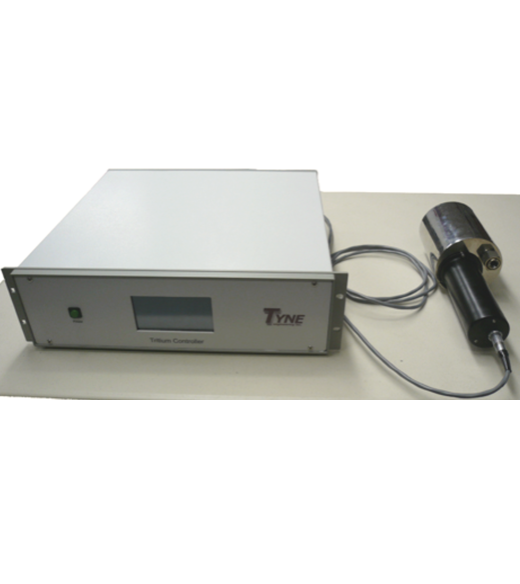

Tyne’s Tritium Controller is the main data processing centre for many of our tritium monitoring configurations. It is suitable for in-line monitoring of process systems, glove box monitoring, stack monitoring, room air monitoring, and other applications such as with Tyne’s tritium-in-breath analyzer. It can be configured for a variety of tritium monitoring requirements, including inputs from one or two ion chambers of different sizes and sensitivities (see Tyne’s 1000cc ion chamber and 10cc ion chamber), multiple alarm configurations, and multiple range configurations.

- Large flat panel touch screen.

- Controls up to two detectors.

- Dual Alarm per channel, local and remote.

- One Touch auto zeroing.

- 4-20 mA, 0-10V or RS232.

- Smooth auto ranging across 9 decades.

The Tritium Controller carries out the signal processing for multi-range tritium detector heads (ionization chamber with preamplifier). It is operated by a large touch screen mounted on the front panel. It has an easy-to-read display and a full set of menu options.

The controller seamlessly auto ranges up to two detectors across 9 decades. Each channel has two user-settable alarms. Each alarm has a local visual and audible annunciation as well as a 30 VDC/ AC 1A relay for a remote alarm.

The multi-range function gives the maximum sensitivity as well as a very large dynamic measurement range from 1 μ Ci/m³ to 1 Ci/m³, facilitating tracking of the total tritium inventory within the loop being measured.

With either a voltage or a current output option, digital range indication or RS-232 output, integration into a data handling system is easy.

The measured signal is also provided in analog form as either 0-10V or 4-20mA. The controller may be connected to a computer through the digital RS232 for remote display of measured values.

To help compensate for any background drift in the detectors, the controller has a simple one touch auto-zeroing function. This will zero the entire system across all the measurement ranges.

The controller comes in a standard 3U (4.5”) 19” rack-mountable enclosure.

The detection heads can be installed remotely up to 100m from the controller. The detector heads can be either a 1000cc or 10cc detection volume. The 1000cc volume gives the maximum amount of sensitivity to 1 μCi/m³. The 10cc volume has a “virtual wall” comprising two nesting cages. This gives the highest range of 10,000 kCi/m³ with minimal tritium contamination due to the small metal surface area. Both detector heads have a small in-line footprint with VCR 8/VCR 4 connections, ideal for installing directly into the piping system. They are both pressure vessels that can handle up to 150 psig, can be heated to 350°C without damage, and are 1×10-9 atm cc/s helium leak tight to conform to current tritium handling standards. The detector heads are of stainless steel construction with a ceramic insulator and an electro-polished interior to minimize tritium surface contamination. In the event of contamination, the detectors are easily decontaminated by flushing them with air.

For gamma compensation, a second detector head may be installed alongside the first head that is measuring the process loop tritium concentration. The compensation detector head, which has no gas flowing through it, will measure the signal from gamma sources and can be subtracted from the detector head that is measuring the gas in the process loop.

The external electronics of a detector head are inside an enclosure that can be made leak tight and can be connected to a purge gas. This will protect the detector heads in an explosive atmosphere so they may be placed in a hydrogen environment. Purging the electronics to provide cooling is also suggested if the detector head is operated at temperatures exceeding 50°C.

related Tritium In Process tubing Monitoring Products

Tyne has successfully designed, fabricated and tested in-line process tritium monitors for process and experimental applications across multiple industries with a wide scope of clients in the nuclear power sector. Our monitors are uniquely simple and compact in design, ultrahigh vacuum compatible, and bakeable to 350°C.