Stack Monitoring Systems

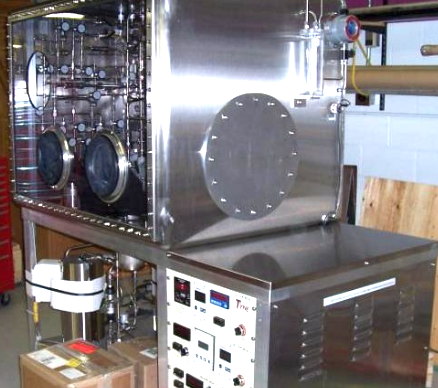

Tyne’s stack monitors are used to assess presence of particulate, iodine, and tritium in the exhaust ducting or plant exhaust stack.

- Equates sample to stack flow.

- Determines overall contamination in stack.

- Measures duct airflow.

- Extracts a measured sample of exhaust air.

- Stack and duct monitoring for tritium.

- Measures for particulate and iodine.

Tyne has a primary interest in the measurement of tritium in stack gases. Other contaminants may also be included, or in some cases the customer may wish to determine the nature of the contaminants. For example, they may wish to know whether tritium discharges are elemental or HTO, or may wish to know if betas measured are in the form of tritium or carbon-14.

To determine stack flow, Tyne uses Sierra flow measuring equipment. This comprises a stack insertion probe through which a representative air sample can be taken from the duct. This process considers the size and shape of the duct. The sample will be processed through custom-made equipment designed to meet the purchaser’s requirements, measured for tritium through conventional detection equipment, totalized, and then compared with the full flow through the duct to determine the total tritium or other components released to the stack.

Tritium stack monitors can be provided with computer controls, permanent computer read out, monthly or continuous collection of data etc to meet individual requirements of clients and regulatory authorities.

Tyne’s flow measurements are controlled via sensitive mass flow controllers and meters; Tyne will provide calibration curves, operating and maintenance manuals, and other documentation required by the purchaser.

Tyne designs and builds to an ISO 9001:2015 Quality Management Program.

Because of the wide variety of stack monitors and end user specific requirements we have not attempted to provide any specifications. Please contact us to discuss your individual requirements.

Please contact us for details.

Related Tritium Handling systems

For over 25 years, Tyne Engineering has been customizing tritium handling equipment and systems for our valued clients worldwide. Our technology is designed and built using high vacuum technology. All pumps, valves and fittings are subject to our stringent quality standards.