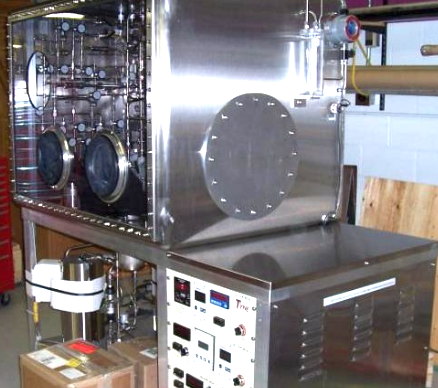

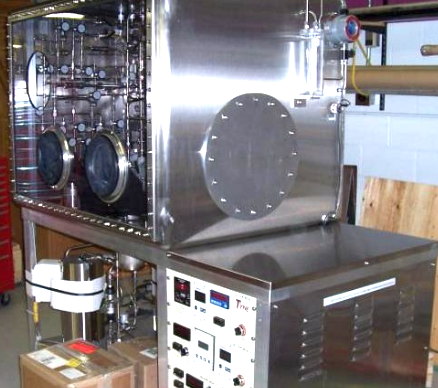

Custom Nuclear grade Gloveboxes

Tyne designs and builds custom laboratory gloveboxes to client-specific needs and to the requirements of the system to be contained. Most of Tyne’s glove boxes have been designed and built to meet the requirements of tritium handling systems where leak tightness is important and the need for good access and easily cleaned parts is essential.

- 11 gauge stainless steel (heavier gauge is can be supplied).

- Smooth, rounded corners that are easy to clean.

- Leak tight to 1×10–5 cc/sec.

- 12 mm windows in reinforced polycarbonate or Mygard.

- High leak integrity feed throughs.

- Antechambers.

Windows can be made to suit (max 1220 mm x 2438 mm), though they are designed for a standard bolt spacing of 60 mm to ensure good leak tightness. Window sealing utilizes a Tyne custom-designed soft rubber extrusion made to fit 12.7 mm windows.

Aluminum is frequently used for supports and other devices where light weight is beneficial.

Stiffeners can be built into the box to support heavier equipment. Some typical specifications of laboratory gloveboxes are outlined below:

Dimensions of up to 3m high x 2m wide x 6m long. Materials of construction are stainless steel for the box. Uses architectural stainless steel extrusions with rounded corners.

Leak rates of 10-5 cc/sec as measured using a helium sniffer probe when the box is filled with helium. Stud welded bolts for windows and other attachments minimize contamination traps.

Laboratory gloveboxes can be made to any shape. The following example comprises a controlled atmosphere box for tritium, a LN controls box to exclude moisture and prevent icing, and an air compartment for equipment attached to the box.

Gloveboxes can be made in a variety of shapes. Numerous additions to the glove boxes are possible, including transfer ports, lights, electrical and pneumatic feedthroughs, sliding tables and internal lifting equipment.

Please contact us for details.

Related Tritium Handling systems

For over 25 years, Tyne Engineering has been customizing tritium handling equipment and systems for our valued clients worldwide. Our technology is designed and built using high vacuum technology. All pumps, valves and fittings are subject to our stringent quality standards.