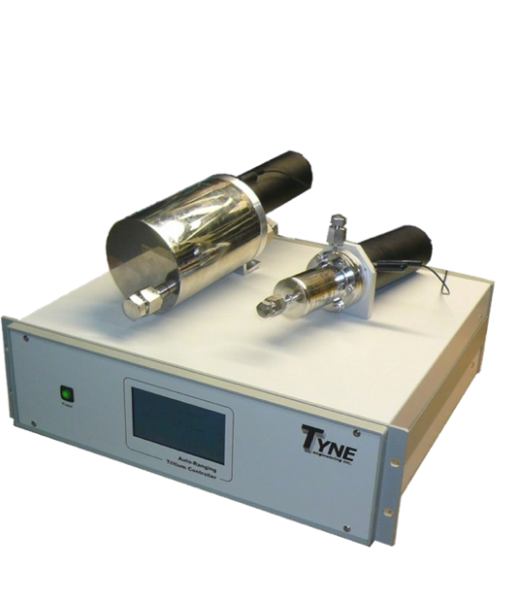

1000 CC ION CHAMBER

Model 7002-1000-001

The 1000 cc Ionization Chamber is designed as a robust, fast flow, bakeable radiation detector. With the small footprint and VCR8 connections, the chamber is easily incorporated into any process system. The specialized ceramic feed through allows a bias of up to 100V and an anode signal as low as 1 fA (corresponds to 1 μCi/m3 of tritium). When combined with Tyne’s preamplifier and controller package or signal processor, this makes an ideal tool for measuring tritium gas in any process.

Note: For higher tritium concentrations, please see Tyne’s model 7047 10cc ion chamber.

- 1000cc ion chamber suitable for μCi/m3 to Ci/m3 of tritium.

- Bakeable to cleanse contaminated surfaces of the ionization chamber

- Full vacuum to 150 psig.

- Precise, tested and proven 1000cc geometry.

- Can bias anode up to 100V from ground.

- Inlet precipitator.

- Can be used in explosive environment with additional purge equipment.

- Use in a process line or for room air measurements.

- Flows up to 1 l/s.

The 1000 cc Ion Chamber is designed to be an in-line process gas radiation detector with the most typical application being tritium. The inlet and outlet VCR 8 connectors allow the chamber to be easily mounted into an existing process line.

The internal anode is connected to a floating BNC which can be biased up to 100 VDC. The high resistance ceramic of the feed through allows the ionization chamber to mea- sure ionization currents as low as 1 fA (1 μCi/m³ of tritium). The bias voltage is also connected to an inlet precipitator to remove any ionized particles carried into the chamber. The maximum inlet flow rate of 1 L/s ensures that all particles are neutralized before entering the chamber. The ionization chamber is an approved pressure vessel that registered up to 150 psig. It is bakeable up to 350°C and is 1x10E-9 cc/sec helium leak tight. The electro-polished interior ensures low tritium hang up, but in the case of contamination the chamber is easily cleaned by heating with a dry air purge.

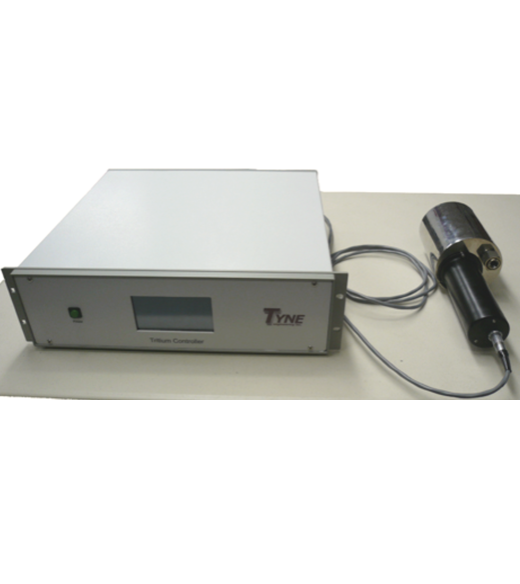

The ionization chamber is typically connected to the Tyne Engineering preamplifier or signal processor. The preamplifier is a multi-ranged amplifier that connects to a remote controller. This gives the user the maximum flexibility for measuring the amount of tritium, auto zeroing and alarm functions. The signal processor is a precision device that provides the bias and converts the 1 fA signal to an easily handled 0 – 10 V signal that can be integrated into any existing data acquisition system.

related Tritium In Process tubing Monitoring Products

Tyne has successfully designed, fabricated and tested in-line process tritium monitors for process and experimental applications across multiple industries with a wide scope of clients in the nuclear power sector. Our monitors are uniquely simple and compact in design, ultrahigh vacuum compatible, and bakeable to 350°C.