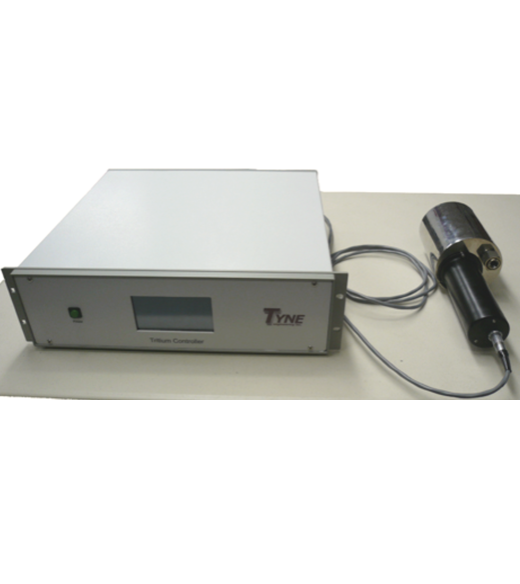

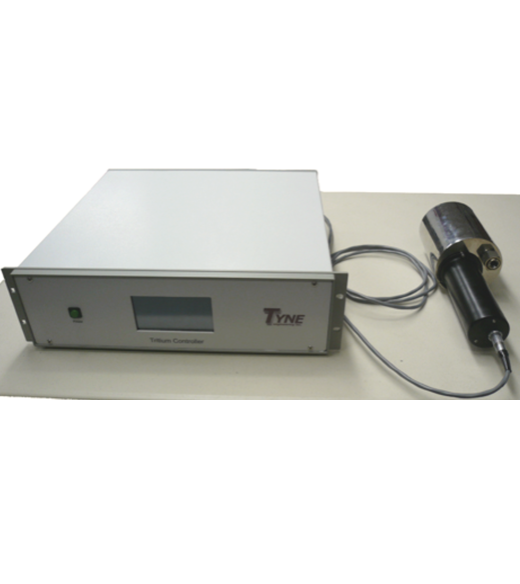

Single Range Tritium Signal Processor Kit

Model 7501-TSPKIT-001-C

The Single Range Tritium Signal Processor is used to measure the amount of tritium directly in line of a process loop in real time and transmit a 0 – 10V output signal. The unique small footprint detector head has the ability to handle up to 150 psig. It is leak tight and can operate at elevated temperatures. Up to 10 transmitters may be powered by one low cost power supply, making this the most cost effective solution for a process with many detection locations.

- Direct inside process line installation.

- High sensitivity of 1 μCi/m3 detection limit.

- 150 Psig Pressure vessel.

- Operates at temperatures above 100°C.

- Leak tight to 1×10-9 atm cc/s.

- 0 – 10 V output for integration into data systems.

- User selectable scale of up to 10,000 units.

- Low cost.

The Single Range Tritium Signal Processor is the most cost effective solution for measuring multiple locations in a process loop in real time. The detector and transmitter are packaged into a single small footprint device that can be located directly in-line with your process.

Only the power line, which can daisy-chain up to 10 units, and the BNC voltage output are needed to measure the activity in your process. The Single Range Tritium Signal Processor is user selectable between 1µCi/m³ to 10,000 kCi/m³, with 10,000 measurement steps. For example, one unit can measure from 1 µci/m³ to 10,000 µCi/m³ while the second unit in the line can measure from 10 mCi/m³ to 100 Ci/m³. The measurement signal is mapped to a voltage output from 1 mV to 10,000 mV which can be measured by a simple volt meter or incorporated into a suitable data acquisition system.

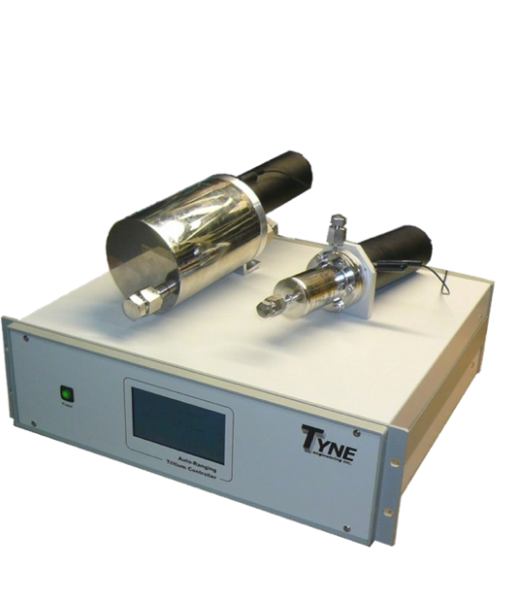

The detector heads can be either a 1000cc or 10cc detection volume. The 1000cc volume gives the maximum sensitivity of 1 µCi/m³. The 10cc volume, which has a “virtual wall,” gives the highest range of 10,000 kCi/m³ with very little tritium hang up. Both detector heads have a small in-line footprint with VCR 8 connections which are ideal for installing into preexisting piping. They are both pressure vessels that can handle up to 150 psig, can be heated to 350°C without damage, and are 1×10-9 atm cc/s helium Leak tight to conform to current tritium handling requirements. The detector heads are of stainless steel construction with a ceramic insulator and an electro polished interior to minimize tritium surface contamination. In the event of contamination, the detectors are very easily flushed with air to decontaminate them.

The external electronics of a detector head is inside a leak tight enclosure that can be connected to a purge gas supply. This will make the detector heads explosion-proof so they may be placed inside a Hydrogen environment. Purging the electronics is also suggested if they detector head will be operated at temperatures higher than 50°C.

related Tritium In Process tubing Monitoring Products

Tyne has successfully designed, fabricated and tested in-line process tritium monitors for process and experimental applications across multiple industries with a wide scope of clients in the nuclear power sector. Our monitors are uniquely simple and compact in design, ultrahigh vacuum compatible, and bakeable to 350°C.