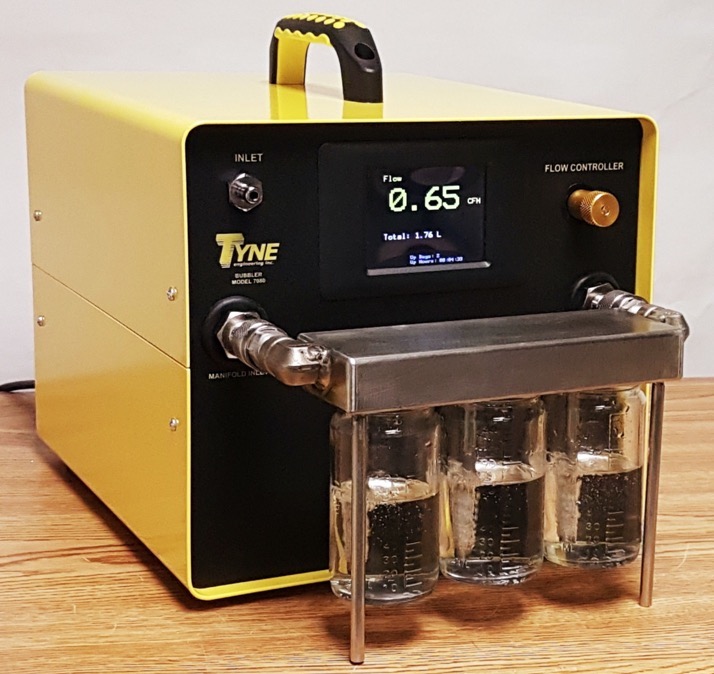

Tritium Bubbler System

Model 7080

Tyne’s model 7080 is a classical tritium bubbler system for collection of workspace or environmental samples from ambient air. With the recognized fast conversion dynamic of free tritium to THO, the requirement for a catalytic furnace to convert free tritium into THO prior to sampling is avoided and a direct three stage bubbler system implemented.

- 100% pure ethylene glycol is the recommended absorbent with multiple stages implemented to ensure 100% capture of all water vapor from the air stream being sampled. Under normal operation, the first bubbler removes over 95% of water vapor, including THO with the balance being removed in the second bubbler. The third bubbler is normally only for insurance.

- Bubbler vials can be provided between 20ml to 125ml with minor adjustment to the bottle rack to account for different vial threads and diameters.

- Any carryover from the bubblers is captured in an internal reservoir, thus protecting the flow metering equipment and pump from water/glycol ingress and potential for tritium contamination.

- A calibrated flow meter is used to monitor the gas flow through the system. This provides accurate momentary flow rate information and a total flow reading. Settings are available via a simple touch screen.

- An efficient positive displacement pump is used to draw the sample gas through the system and a manual needle control valve is used to regulate air flow 0 to 600ml/min. Recommended flow range is 50ml to 300ml/min depending upon sample bottle size selected.

The Tyne tritium bubbler system is designed for reliable, long term operation in diverse locations. It cannot, however, be used in outside locations without secondary protection in a weatherproof cabinet.

The system itself comprises of a filtered inlet, either mounted directly on the 7080 case or alternatively, via an induction tube, at a location chosen by the customer.

After filtration, the sample passes sequentially through three bubblers where the sampled gas stream is brought into contact with the selected absorbent by use of sintered metal spargers installed on the end of each bubbler inlet tube.

Once through the bubblers the air flow passes through a small disentrainment vessel mounted inside the instrument case. This is intended to remove any droplet carryover from the sampled gas stream before it reaches the mass flow controller and pump.

Flow is monitored by use of a calibrated flow meter to give high flow measurement accuracy and is controlled using a manual control valve installed on the mass flow meter body.

A positive displacement pump is used to draw the sampled air through the bubblers and to exhaust it locally, away from the sampling location, to ensure that back-flow is minimized.

Please contact us for details.